Engineering and Simulations - Andaltec

Andaltec es un centro tecnológico especializado en sistemas de iluminación para automoción, plásticos en contacto con alimentos, prototipado y materiales.

plastic, lighting, automotive, car, packaging, food, test, migration, enac, prototype, engineering, headlamp, projector, rear, lamp, material, polymer, painting, coating, 3d, printing, simulation, optic, robot, training, cad, project, technological centre, innovation, martos, andalusia, r d, led

28618

page-template,page-template-full_width,page-template-full_width-php,page,page-id-28618,page-child,parent-pageid-28602,bridge-core-1.0,ajax_fade,page_not_loaded,,qode_grid_1300,side_area_uncovered_from_content,footer_responsive_adv,qode-content-sidebar-responsive,qode-theme-ver-10.1,wpb-js-composer js-comp-ver-6.10.0,vc_responsive

Engineering and Simulations

Engineering and simulations

ANDALTEC offers its customers all the tools needed to develop their products through our Engineering department. We can act as consultants or assume the whole product development.

Our staff, made up by more than 50 engineers, technical engineers and design technicians, has the only goal of helping our customers to complete their projects successfully.

The Engineering and R&D Projects departments work side by side to integrate all the development stages for products, from their conceptual design to their pre-industrialisation phase.

- Definition of technical specifications for a new product: customer requirements, legal requirements, homologation or EC Market requirements…

- Design risks analysis (FMEA of products and processes).

- CAD design of plastic and metal parts, using CATIA V5 and SOLIDWORKS software.

- Conceptual and detailed design.

- Choice of materials and manufacturing technology.

- Estimation of production, product and tooling costs.

- Prototyping of mounted assemblies and plastic parts.

- Validation tests.

PRODUCT SIMULATION

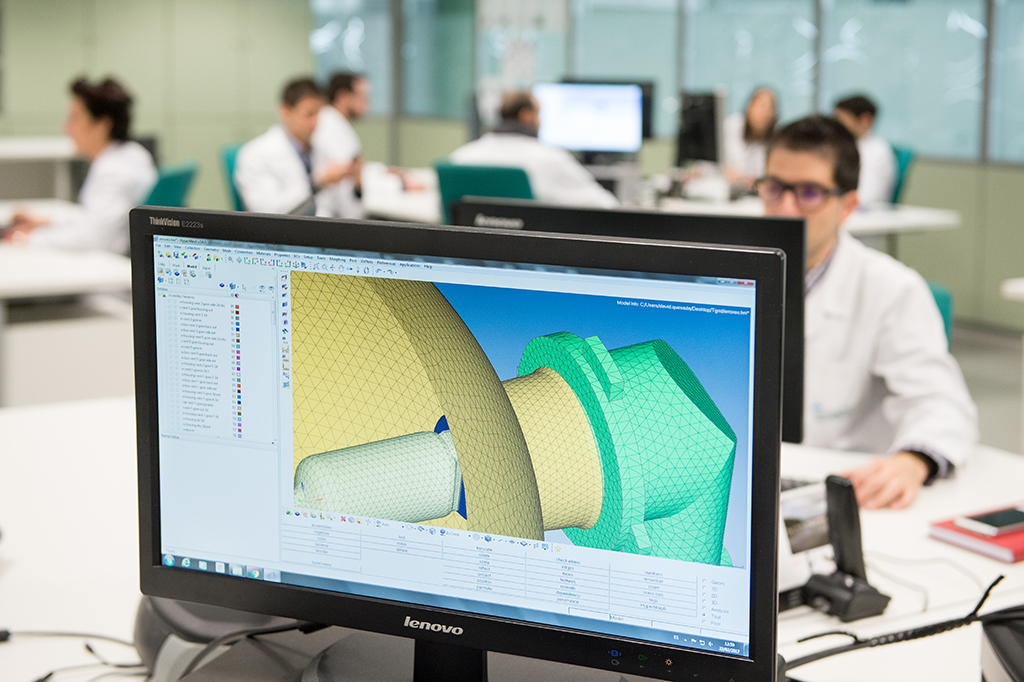

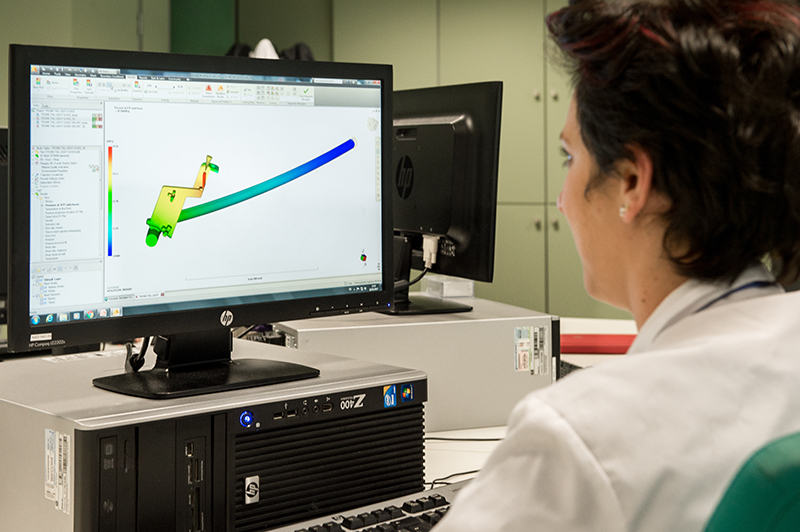

Andaltec can offer a wide range of tools to optimise and validate product design, reducing every project’s development time, as well as prototype and non-quality costs.

- Mechanical simulations: Static, dynamic and impact analysis of a part confronted to real requests to check product specifications; analysis for geometry optimisation using OPTISTRUCT, comprising software such as RADIOSS, ANSYS, CATIA, GPS or OPTISTRUCT.

- Thermal simulations: System analysis using specified thermal charges, temperature fields and thermal resistance of system components, employing ANSYS FLUENT software.

- Condensation simulations: Analysis of change from gas to liquid phase using specified thermal charges, with ANSYS FLUENT software.

- Optical simulations, using Lucidshape and ASAP software.

PROCESS SIMULATION

In order to carry out the full development cycle for a product, we have simulation tools for the different plastic manufacturing processes.

- Injection: Simulation and analysis of the plastic injection process through MOLDFLOW. This tool allows to study the injection process in its different configuration settings: Multiple injection, sequential, overmoulding, pressure injection…

- Extrusion: Continuous extrusion using HYPERXTRUDE software. Flow simulation through the die head, taking into account the material–machine interaction in order to define the optimal transition profile.

- Tooling: Part deformation during the tooling process using HYPERFORM software. Evaluation of process and product feasibility compliant with definition in order to discard potential risks.

- Simulation of manufacturing process for materials composed of LCM (Liquid Composites Molding): Resin Transfer Molding (RTM), Vacuum Assisted RTM (VARTM), Vacuum Assisted Resin Infusion (VARI), using HYPERMOLD software.

- Simulation of preforming process in dry fibers or thermoconforming of pre-impregnated materials made from thermostable or thermoplastic resins (RADIOSS software).

- Simulation of thermoforming process. By means of T-SIM, we can predict the mechanical behaviour of a part during the manufacturing process and the thickness distribution of the final plastic wall, based on specific processing parameters. Distortion/pre-distortion of images can also be predicted.